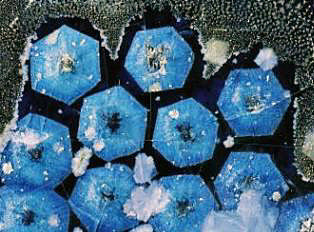

Oil Spot Tea Bowl, Jin Dynasty (Sung 12th-13th Century). Seikado Foundation Tokyo. D: 12 cm

Crystalline glazes appeared already during the Chinese Sung period of the 12th century (Japanese and Korean oilspot and kaki glazes).

In Europe, the history of the crystal glazes begins at the 19th century in Sèvres France, followed by the Royal Porcelain Manufacture of Copenhagen and the famous Meissen Manufacture in Germany.

In the 20th century the german potters Richard Bampi and Hubert Griemert and in Switzerland Arnold Zahner experimented with crystal glazes. In all generations this type of glazes all have two things in common: The hazard and a high estethic attraction.